Marine Cathodic Protection Brochure

Overview

Seawater is one of the most corrosive of naturally occurring environments. Metallic structures immersed in seawater are subject to severe corrosion including close inshore structures such as harbours, jetties and piers, constructed from sheet or tubular piles.

It is essential that these structures be protected against the ravages of corrosion by the application of cathodic protection in order to achieve or exceed its design life

What BAC Can Offer

BAC specialise in the design, manufacture and installation of impressed current cathodic protection systems for large immersed structures such as jetty and harbour tubular piles, sheet piles, dolphins and pontoons. Impressed current cathodic protection current is provided by either manual or automatically controlled transformer rectifiers powering impressed current anodes specifically designed to operate in the conditions prevalent on site.

BAC carry out their designs in accordance with international standards under the control of our ISO 9001:2015 certified quality management system. System design lives can be in excess of 25 years as standard. BAC can also repair and rehabilitate existing systems for asset life extension. With integrated Infinity Remote Monitoring and Control your CP system status can be viewed and controlled remotely to save costly and risk heavy site services.

Cathodic protection of Harbours and Jetties

BAC willingly provides advice and outline system design for cathodic protection of Harbours and Jetties. In order to do this, as much of the following information should be provided - the more information supplied, the closer our proposals will be to the final designs:

- Type of piling

- No/length of piling

- Depth of piling above and below seabed

- Specification for pile coating

- Method of continuity bonding

- Layout drawings

- Classified hazardous area

- Facilities for isolation from other structures

- Power supply type and availability

- Existing CP Systems

Ships and Boats (Impressed Current Systems for Water Jets on Fast Ferries).

The material used for the hull of fast aluminium vessels withstands corrosion in seawater very well under normal operation conditions, due to the passivating oxide layer of the surface.

Sacrificial anodes made of Aluminium alloy are normally used for cathodic protection of the critical areas, but for waterjets and thruster tunnels with high water velocity, practical experience have shown, that the lifetime and capacity of sacrificial anodes are limited, and do not give sufficient protection.

BAC has solved the above mentioned problem by the design of an Impressed Current Cathodic Protection (ICCP) system. The "Award" systems, which have been installed in a number of vessels already, secures full protection and avoid the risk for overprotection, by means of strategically installed reference electrodes, used for control and monitoring.

Images for some recent ICCP projects in the Caribbean and Caspian for jetty and port structures.

Case Histories & Clients

|

Project

|

Country

|

Scope

|

Years

|

Value

|

|

Tanap Project - Turkey

|

Turkey

|

Design Manufacture Supply of Cathodic Protection equipment include 32 Transformer Rectifiers , MMO Anodes, Pin Brazing etc

|

2016-2018

|

>$250,000.00

|

|

Mombassa To Kenya Pipeline

|

Kenya

|

Design Manufacture Supply of Cathodic Protection & Corrosion Monitoring equipment

|

2015-2016

|

>$350,0000.00

|

|

Southern Swamp Associated Gas Solution (SSAGS)

|

Nigeria

|

Design Manufacture Supply of Cathodic Protection equipment

|

2016-2017

|

>$350,000.00

|

|

TAP Project (Trans Adriatic Pipeline)

|

Greece / Albania / Italy

|

Design Manufacture Supply of Cathodic Protection equipment

|

2018-Present

|

>$1,000,000.00

|

|

Major Oil Field Development Project

|

Kazakhstan

|

Design Manufacture Supply of Cathodic Protection equipment

|

2017 to Present

|

>$5,000,000.00

|

|

Turkmenbashi International Seaport

|

Turkmenistan

|

Design, manufacture, supply, install and commission of a Cathodic Protection system for > 3000 tubular steel piles on a sea port structure.

|

2016 to 2019

|

>$2,000,000.00

|

|

Petrojet EGPC Tank Farm Project

|

Egypt

|

Manufacture, supply, of a Cathodic Protection system for 29 Crude Oil Tanks > 100m Diameter & 7 Water Tanks

|

2020

|

>$2,500,000.00

|

|

Al Dabb’iya Thammama Zone B Transition Zone Development - Phase 1

|

UAE

|

Manufacture and Supply of Internal Corrosion Monitoring Systems

|

2020

|

>$400,000.00

|

Process plant, refineries, tanks and well casings, whether in the Oil, Gas, Petrochemical, Water or other industry represent a huge investment and are required to operate continuously.

Pipelines whether in the Oil, Gas, Petrochemical, Water or other industries represent a huge investment and are required to operate continuously and safely for their entire design life.

BAC has built a reputation for providing technically sound and cost effective solutions for corrosion control through CP to complex power station structures.

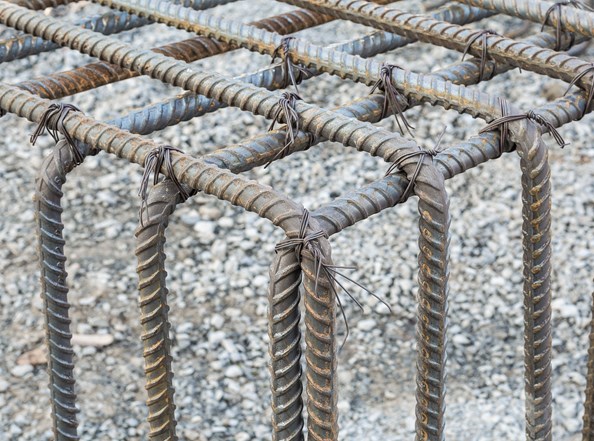

BAC provide a complete portfolio of products and systems to protect, repair, monitor and maintain concrete structures where steel reinforcement is liable to corrode.

Through our Brightbond division we supply Pin Brazing equipment and accessories worldwide to the rail market for track and signalling connection applications.