Pipelines

Pipelines whether in the Oil, Gas, Petrochemical, Water or other industries represent a huge investment and are required to operate continuously and safely for their entire design life.

Pipelines whether in the Oil, Gas, Petrochemical, Water or other industries represent a huge investment and are required to operate continuously and safely for their entire design life. Anything that detracts from this goal is totally undesirable and every endeavour must be made to prevent all occurrences that might jeopardise the safe and efficient running of the plant and operation.

Corrosion is one of those occurrences that will affect the safe and efficient running of the plant with the costs for plant shut down, lost production, product loss, environment contamination and loss of customer confidence running into millions of pounds.

BAC will provide you with the insurance against these costs by designing, supplying, installing, commissioning and maintaining cost effective, efficient CP systems that will mitigate corrosion. BAC provides a complete portfolio of CP products from simple but effective Galvanic systems to sophisticated ICCP systems with full remote Monitoring and Control capability.

BAC willingly provides advice and outline system design for cathodic protection of pipelines. In order to do this, as much of the following information should be provided - the more information supplied, the closer our proposals will be to the final designs:

BAC have undertaken thousands of kilometers of AC modelling work to assist our clients in mitigating against AC induced corrosion and ensuring safety on their pipeline routes.

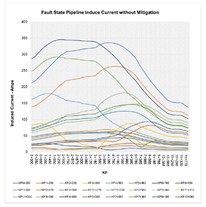

Where pipelines cross or run parallel to AC power lines the possibility of AC induction onto the pipeline can cause both a corrosion risk, and a step touch potential risk to people.

The following operational criteria are applied to the design of the AC mitigation system:

-Steady state touch potentials at pipeline above grade appurtenances and facilities shall be below 15VAC (STP).

-Maximum AC current density shall be less than 20 A/m2.

-Step and touch potentials at exposed pipeline sites during fault conditions shall be within IEEE standard 80 safety criteria.

By entering the following information into the software programme we can accurately and effectively model the pipeline in steady state and fault conditions and provide detailed mitigation plans and measures.

-Soil resistivity

-Pipe diameter

-Pipe buried depth

-Pipe coating type and thickness

-Coating resistance

-AC power line to pipeline separation distance and angle

-Tower configuration

-AC conductor configuration

-AC load current

-AC fault current

BAC Manufacture a range of products to assist with AC Corrosion and safety issues including:

-Infinity EDD devices (Solid State Polarisation Cells).

-Zinc Ribbon and Zinc Gradient Mats

-AC Remote Monitoring

For any Pipeline Owner, the most important asset is the pipeline itself. The continued safe and economical operation of the pipeline is an absolute essential and proving the ongoing fitness for purpose is increasingly becoming a regulatory requirement.

BAC can provide a service to prove the effectiveness of the corrosion control systems applied to the pipeline which will give the assurance that corrosion is not taking place along the whole length of the pipeline.

For new pipelines, it is necessary to prove that the pipeline meets all the design requirements. For corrosion control, this means proving that the coating has been applied correctly and that major faults, construction damage etc are repaired and that the criterion for cathodic protection has been achieved over the entire surface of the pipeline at commissioning stage.

For older pipelines age deterioration and disbondment of the coating may have taken place. It is essential that the quality of the coating and the cathodic protection are assessed and, where required, full rehabilitation of the coating and/or the cathodic protection is carried out.

BAC has surveyed many thousands of kilometres of pipelines around the world carrying out full audits of CP Systems and Close Interval Potential Surveys, Pearson Surveys, Current Attenuation Surveys and DC Voltage Gradient Surveys,

BAC teams are led by experienced and qualified Engineers and Technicians, fully able to asses the quality of data being collected. Full detailed reports are provided with recommendations and costings for any necessary remedial work.

BAC will provide all the materials and services necessary for your survey and rehabilitation work to restore the integrity of your pipeline corrosion control systems.

For further information please contact us using the following:

Enquiry FormEmail: sales@bacgroup.com

Phone: +44 (0) 1952 290321